At a warehouse in La Mesa, CA, a forklift operator had just finished loading a delivery truck when he backed up. Although he had checked for obstacles, a worker entered his path and had turned his back on the forklift. The forklift rolled over his foot, fracturing his ankle and foot.

In another case, a punch press operator at a computer components manufacturing was killed while at her workstation. A forklift nearby struck a metal scrap bin which hit the press. It bounced off, hit the forklift again, then shoved the press back against a corner where the worker was crushed.

While important tools in the workplace, forklifts can be dangerous if not operated and equipped properly. In both of these cases, forklift operators were trained and certified. Yet, it took just one moment of inattention to detail to result in a serious injury or death.

More than 95,000 injuries happen annually. On average, 87 workers lose their lives each year due to accidents involving forklifts.

The cost is staggering. While you can’t put a price tag on the impact of a fatal accident to the worker and their families, you can’t quantify the costs for other things that arise in the wake of a forklift accident, such as:

- Workers’ Compensation claims

- Fines

- Lawsuits and legal costs

- Equipment damage and repairs

- Loss of production

The average cost to a company for each forklift accident is $184,000. Repeat incidents can escalate that cost quickly with fines amounting to more than $120,000. When you consider that more than 10% of forklifts in the US are involved in an accident every year, it’s a high price to pay.

The saddest part in all of this is that nearly every accident is preventable with the proper training, operation, and equipment.

Preventing Forklift Accidents

Forklift operators often work in close quarters and in areas where other people are moving around. That’s why nearly 80% of forklift accidents involve a collision with a pedestrian.

Safety training is essential, but it only works if everyone follows the procedures every time. As you can see by these sobering statistics, training alone doesn’t prevent accidents. Warehouses and other facilities that use forklifts need a better solution to prevent accidents.

The Smart Proximity Detection System (SPDS) from Laserglow TechnologiesTM is that solution.

SPDS used wireless technology to measure the distance between vehicles and pedestrians or other vehicles and provide an early collision warning. Devices on powered vehicles monitor the area around them, constantly scanning for potential collisions. Workers can use tags to warn them of potential dangers by vibration or audible alerts. High-traffic areas, intersections, and blind spots can be equipped with fixed devices to monitor accident-prone areas.

Smart Proximity Detection Systems create a 360-degree safety bubble around forklifts to warn operators and pedestrians in a variety of situations.

Preventing Forklift and Pedestrian Accidents

Vehicles can be equipped with tags that provide alerts when pedestrians are close to entering the danger zone. At the same time, workers can wear small tags that alert them at the same time. This two-way communication allows both forklift operators and pedestrians to get immediate warnings so they can avoid collisions.

The best proximity detection systems will provide programmable detection zones to indicate different levels of notifications. For example, there can a Warning alarm when someone comes close and a Danger alarm when imminent collisions may occur. These zones are configurable and can trigger different system reactions automatically. You may want audible, visual, or vibration alarms for Warnings and Vehicle slow down or stops for Danger alerts.

Preventing Vehicle Accidents

The same process works to help avoid accidents between multiple powered vehicles. Vehicle tags work in concert to detect nearby vehicles and warn operations. Once forklifts and other vehicles are equipped with the SPDS system, they will constantly communicate and detect vehicles that are also equipped.

Detection can be configured with ranges up to 30 meters. Even if a vehicle is moving through a blind spot without a clear line of sight, the system will warn drivers nearby so they can avoid collisions. The best SPDS systems will force action by the driver. For example, when vehicles enter a potentially hazardous situation, an audible alarm will sound. Vehicle drivers must press a button to clear the message to mute the sound or wait until the other vehicle has exited the danger zone.

Blind Spot Warnings

Every facility has blind spots, such as at the end of racks. Pedestrians might be exiting a row while a forklift is traveling by. Neither party may be able to see the other until it’s too late. By mounting SPDS devices at corner intersections or other blind spots within a facility, it can trigger warnings such as flashing red lights to indicate caution.

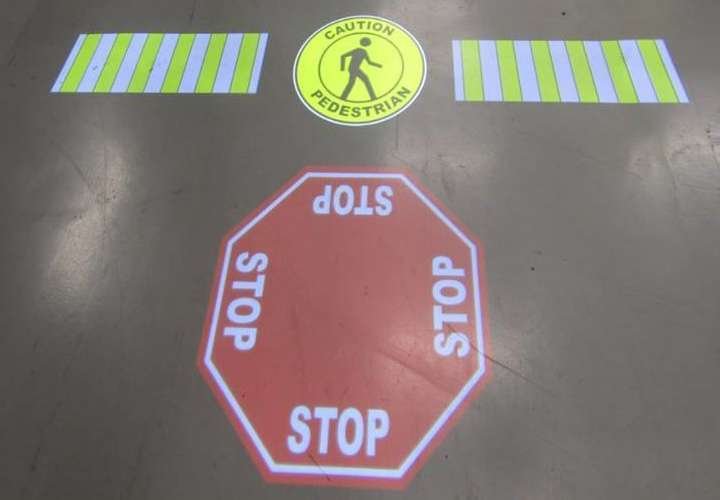

Flashing zone beacons can be installed anywhere, including aisle entrances and exits, intersections, high-traffic areas, gates, or other places where visibility is limited. Virtual signs can also be deployed so that when a forklift or other powered vehicle enters warning of danger zones, a warning sign is projected onto the floor. While the vehicle driver gets a warning through their device that provides audible or vibration alarms, they also will see messages, such as Stop, Caution, etc. visually.

Automatic Gate or Access Controls

SPDS can also limit access to certain areas and warn about automated gates. You may limit speeds in high-risk areas or zones.

The Benefits of Smart Proximity Detection Systems

Smart Proximity Detection Systems operate in real-time to monitor, control, and predict potentially dangerous situations to ensure a safe distance is maintained. Because it uses RF frequency, it can detect pedestrians through obstacles, such as racks or pallets.

The Smart Proximity Detection System from Laserglow Technologies provides other benefits, including:

- Highly Accurate: Uses Ultra-Wide Band (UWB) RF technology for precise measurement

- 360 Degree Protection: Can detect multiple vehicles or pedestrians at the same time

- Easy to Install and Use: Can be used right out of the box without the need for registration or calibration

- Bilateral Alarms: Both drivers and pedestrians receive audible or vibration alarm (or both).

- Can be Installed on Any Equipment: SPDS is OEM-independent, so it can be used on mixed fleets, fitted to new forklifts, or retrofitted onto existing equipment. IT is compatible with all major forklift models.

- Configurable: Different alert zones can be set up for various scenarios, such as customized alert zones for vehicle to pedestrian or vehicle to vehicle interaction

A safer work environment pays dividends in other ways as well. When you have trained workers that are equipped with the proper safety equipment like SPDS, you will also see:

- A more productive workforce

- Less downtime

- Less damage to equipment and property

- Increased equipment life

Go Beyond Training for Forklift Operators and Workers

As part of a comprehensive approach to workplace safety, smart proximity detection can enhance safety and help protect workers and equipment. Along with a formal training program, it can help reduce workplace accidents.

The Occupational Safety and Health Administration (OSHA) requires formal training for anyone operating a forklift, lift truck, or powered industrial trucks in businesses. It is a violation of the law for anyone that has not been trained and certified to operate a forklift. It’s part of OSHA’s requirements that workers have a right to working conditions that do not pose a risk of serious harm. Organizations have a moral and legal responsibility to protect their workers by taking proactive steps to minimize dangers.

Training is important, but for it to be effective, it’s really about how people use the lessons they learned. One significant advantage of using proximity detection safety systems is that it’s a constant reminder of the lessons learned during training. Each time an alert or warning is sounded, it reinforces the training and the need for constant vigilance in the warehouse.

There are a couple of common threads that emerge when you look closely at forklift accidents, according to the National Institute of Occupational Safety and Health (NIOSH). NIOSH investigations into accidents found that workers and employers were not aware of the risks of operating or working near forklifts, didn’t follow OSHA procedures or manufacturer’s warnings, or failed to deploy the proper safety equipment to prevent accidents.

Training and certification of employees along with proximity detection systems can mitigate these risks.

About Laserglow Technologies

Laserglow’s SPDS is a Smart Proximity Detection Safety System that is designed to enhance safety and workflow by limiting access to certain areas and automating controls.

SPDS uses cutting-edge Ultra Wide Band (UWB) RF wireless technology to precisely measure the distance between vehicles and provide access control to restricted areas. It is easy to install without causing any damage to vehicles and features industry-leading proximity detection technology.

SPDS is OEM-independent, so it is ideal for mixed fleets. The system works on robots, cobots (collaborative robots), and AGVs (automated guided vehicles), as well as forklifts and other industrial vehicles.

Contact Laserglow today to explore the benefits of the Smart Proximity Detection System and enhance your workplace safety.